There are several reasons for the deformation, squashing, and buckling of water boreholes.

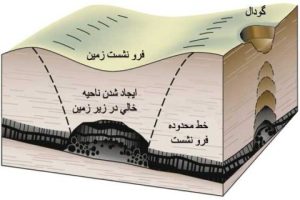

Land subsidence is a major issue caused by overexploitation of water from boreholes leading to the compression of aquifer porosity. When an aquifer is overexploited and its pore water is depleted, the porosity of the aquifer is compacted leading to land subsidence. This compaction leads to the subsidence of the upper layers of the earth, causing the well casing to be drawn down while the lower part of the casing located in the saturated zone remains fixed. This phenomenon is known as buckling or squashing and can occur throughout the plain leading to the collapse of the surrounding formation of the borehole. Land subsidence can occur for recently drilled boreholes and sometimes boreholes may be affected by subsidization without any consideration for the response of the plain. The image below illustrates land subsidence.

Sand production in boreholes can cause damage to the casing. This issue often arises due to an incomplete filter pack. In practice, the filter pack is placed in the annular space between the screen and borehole wall and serves to support the screen within the aquifer to increase the permeability in the zone around the screen and to filter fine-grained aquifer materials (Kim, B. 2014). For a borehole to be designed properly accurate assumptions are necessary. However, direct drilling can result in boreholes with low precision. Due to the low rate of mud drilling exits rock samples from different depths and layers may mix together. Therefore, the bearing rock samples may not be an accurate representation of the depth and layer. Indirect drilling on the other hand has many advantages. The most significant benefit of this type of drilling is that the bearing samples will be a proper representative of the layer being drilled. By understanding the geological layers of the aquifer appropriate selection of the length of the well casing and the size of the screen’s perforations can be made with precision.

Rafferty (2001) presented the design of a desirable gravel pack including the effective grain size, uniformity coefficient, thickness, type of filter pack material, and guidelines for its placement.

Designing a water borehole also involves adjusting the size, material, and thickness of the filter pack. The plan should be operated correctly but there is no device available to regulate the gravel pack arrangement. Bridging the particles of the gravel pack may occur in front of fine particle layers of the geological formation. In such a situation if data about the size of the aquifer’s layers is unavailable then instead of sealing the borehole at these depths sand production can occur. Over time fine particles of the geological formation will enter the borehole due to the absence of the gravel pack producing a gap space within the surrounding area of the well casing which leads to land subsidence. As a result, the well casing will be squashed and deformed.

The filter pack arrangement should be rearranged after drilling. After drilling it is suggested that well development should be performed to rearrange the particles of filter packs. AirShock and Nitro-Pulse® techniques can be used to eliminate the bridges among gravel particles of the filter pack in order to the prevention of sand production and subsequently reduce the possibility of land subsidence.

The vast majority of drilled water boreholes 50 years ago are working properly right now due to the right design of the borehole and filter pack.

Another reason to cut the well casing is to prevent damage caused by the shear forces of the earth, which arise due to the lateral displacement of the earth’s layers. This phenomenon can lead to deformation and harm to the well casing. The pictures below illustrate examples of well casings that have been damaged due to this phenomenon.

To minimize the harmful effects of land subsidence on well casings it is essential to design and implement effective preventive measures.

One of the primary causes of well casing deformation is the production of fine particles and sand.

There are various measures that can be taken to minimize the harmful impacts of land subsidence. These include using appropriate and accurate well design opting for reverse circulation drilling instead of direct circulation drilling incorporating telescopic compressed sections in well casing to counter the forces arising from land subsidence designing the size and thickness of the gravel pack and proper implementation of all these measures.

Although well-casing deformation should be avoided it may occur unavoidably. Fortunately, there are new techniques available for repairing and fixing any damage. Our experts are committed to providing innovative solutions that can restore your damaged water wells.

Reference: